SAMARTH Udyog Bharat 4.0 is an Industry 4.0 initiative of Ministry of Heavy Industry & Public Enterprises, Government of India under its scheme on Enhancement of Competitiveness in Indian Capital Goods Sector.

SAMARTH Udyog encompasses manufacturers, vendors and customers as the main stakeholders. The experiential and demonstration centres for Industry 4.0 have been proposed to spread awareness about I4.0 amongst the Indian manufacturing industries. Five centres of I4.0 having a unique identity for spreading awareness and branding have been sanctioned under SAMARTH Udyog. It is emphasized that these centres would have resource sharing, common platform of industry 4.0 and network each other’s resources so that the utilization of resources is maximised.

In Phase II of the Capital Goods Scheme, C4i4 Pune has been entrusted with the responsibility of establishing 10 additional Industry 4.0 centers at various locations across India.

Five CEFC (Common Engineering Facility Center) Projects are:

- Center for Industry 4.0 (C4i4) Lab Pune

- IITD-AIA Foundation for Smart Manufacturing

- 0 India at IISc Factory R & D Platform

- Smart Manufacturing Demo & Development Cell at CMTI

- Augmentation of Centre for Industry 4.0 & Data Engineering Skill Development Centres at 10 different locations of India

Center for Industry 4.0 (C4i4) Lab Pune

Cyber-physical systems are leading the manufacturing industry into the 4th industrial revolution popularly known as Industry 4.0. It has the potential to address many challenges faced by the Indian industry that hinder its global competitiveness such as the perception of low quality, stiff competition on cost from other nations, low levels of innovation and limited agility to meet rapidly changing customer needs.

C4i4 Lab India is one of its kinds Innovation Centre in the country focusing on Industry 4.0. C4i4 Lab has put India on the list of countries that have taken up dedicated initiatives for the promotion and adoption of Industry 4.0.

The programs of C4i4 Lab would not only strengthen the expertise of companies in manufacturing but also help to develop a sustainable ecosystem that nurtures & drives innovation & growth. C4i4 Lab prepares use cases of Industry 4.0 and demonstrates the benefits to the companies. It provides access to technology and resources in order to support Industry 4.0 pilot projects in companies. C4i4 Lab partners with leading companies to utilize their resources, equipment, and expertise to demonstrate technologies in the experience centers.

| 1 | |

|---|---|

|  |

|  |

IITD AIA Foundation for Smart Manufacturing, CEFC at IIT Delhi Hauz Khas, New Delhi

The CEFC is envisioned as a multi-utility center comprising a set of interconnected smart machinery to represent a miniature, yet feature-rich production system. The National CEFC serves as the primary organization supporting demonstrations, skill development, prototyping, and integrated solutions for smart technology-enabled manufacturing.

As a part of the CEFC initiative, they have established a Cyber-Physical Lab for Smart Manufacturing Research at IIT Delhi's Hauz Khas campus (with a proposed floor area of 1,500 sq. ft.) and a fully equipped Cyber-Physical Factory at IIT Delhi's Sonipat campus (with a proposed floor area of 30,000 sq. ft).

Major activities of the IITD AIA FSM in 2022-23:

1. IAFSM conductedSummer Internships 2022from June 2022 to July 2022. We offered 8 Project Domains for which 852 Candidates applied and 786 Candidates were shortlisted. 101 Candidates achieved Level 1 proficiency. 28 No. of projects done and 18 Candidates were selected for presentation before Jury Members. 61 Candidates completed the Internship and 6 Candidates were awarded with cash prize for Best Project Award

| 2 |

|---|

|

2.IAFSM showcased Robotics domain and related technologies at Robocon 2022 from 16th July2022 to 17th July2022.800-900 students from 50 colleges across India participated in Robocon and interacted at IAFSM stall to see the technology. IAFSM also introduced SDRVS System to verify registration data to permit only valid ID card holders inside the stadium.

2.IAFSM showcased Robotics domain and related technologies at Robocon 2022 from 16th July2022 to 17th July2022.800-900 students from 50 colleges across India participated in Robocon and interacted at IAFSM stall to see the technology. IAFSM also introduced SDRVS System to verify registration data to permit only valid ID card holders inside the stadium.

3.Math Works Day (10thAugust2022): This kind of event is organized to boost The confidence of the stakeholders where they invite their industry clients at IAFSM and our team demonstrates all the developments and technologies. This gives us the advantage to know more about their use – cases and a familiarity with the real-world scenarios.

4.IAFSM organized Training for Hindustan Aeronautics Limited in hybrid mode in December 2022. The training was spread over a period of 60 days online and 5 days on campus where the designed Smart manufacturing curriculum focused on HAL use-cases and Smart Manufacturing Technologies. The participants successfully implemented most use-cases in their organization post the completion of training.

5.IAFSM participated in Automation For Smart Manufacturing in PuneandHosuron22ndDecember2022and24thMarch2023in which we gave Live demonstrations of Assembly Line, Robotic Cell, Welding Cell and other technologies like Augmented Reality, Digital Twin, IIoT, etc. were demonstrated be forehand to the attendees.

5.IAFSM participated in Automation For Smart Manufacturing in PuneandHosuron22ndDecember2022and24thMarch2023in which we gave Live demonstrations of Assembly Line, Robotic Cell, Welding Cell and other technologies like Augmented Reality, Digital Twin, IIoT, etc. were demonstrated be forehand to the attendees.

6.IAFSM participated in Event 3rd International Conference on Digitalization, Robotics and Automation (DRA) - Industry4.0 on 16-17 March2023 at Hotel Crowne Plaza, Gurgaon in which we demonstrated Smart Technologies and functionalities and Live demonstrations from IIT Delhi. Prof. Sunil Jha enlightened the viewers on Essentials of Smart Manufacturing/Industry4.0andtheir implementation.

Smart Factory @IISc , Bengaluru

The CEFC at IISc, known as I4.0forIndia@IISc (pronounced as 'I for India at IISc'), aims to bridge these gaps. It offers a range of services and resources, including:

- 1. Two distinct platforms for demonstrating and exploring Industry 4.0 technologies and capabilities. One platform showcases the potential of networked automation, while the other focuses on smart solutions to enhance labor productivity.

- 2.Integration of smart tools for legacy machines into these platforms.

- 3. Affordable point solutions tailored for Micro, Small, and Medium-sized Enterprises (MSMEs).

- 4. Demonstrations of trade-offs and benchmarking of these platforms using selected Key Performance Indicators (KPIs).

- 5. Training programs for industry leaders, research and development personnel, and emerging professionals in the field of Industry 4.0.

- 6. A homegrown research foundation to support the industry's adoption of Industry 4.0.

- 7. Assistance in the development of indigenous Industry 4.0 standards, protocols, and middleware.

- 8. Hosting international Industry 4.0 conferences and conducting awareness workshops.

- 9. Support for startups in the field of Industry 4.0.

- 10. Providing policy guidance to both industry and government stakeholders.

Major activities of Smart Factory @IISc , Bengaluru in 2022-23

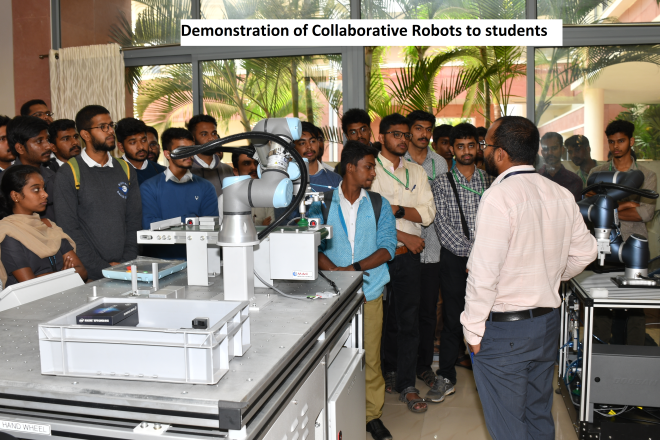

- In Smart Manufacturing and Industry 4.0, IISc provided an ecosystem for awareness, and training of students, academics and professionals in understanding and application of smart manufacturing, digital transformation and production management principles and concepts. Over 9800 given awareness; close to 800 professionals/academics (from 243 organisations, start-ups and institutions) have been given training in workshops and training programmes: PSU, DRDO, OEMs, Start-ups, students etc.

- 20 students have been trained via M Techin smart/advanced manufacturing and joined industry as well CEFCs such as C4I4 Pune to strengthen CG sector. Another 60 are undergoing MTech/PhDin I4.0.

- 6 Research & innovation projects worth INR 5Cr completed with TCS, Yaskawa, Faurecia & Toyota.

- 14 indigenous smart technologies and solutionshave been created in digital twin, virtual reality, robotics, inspection, sustainability, additive manufacturing etc.

- Two of these have been implemented in MSMEs; oneled to a start-up that had attracted INR 50 Lakhs in seed funding. The remaining ones are being developed further before they can be delivered to industry.

- The smart factory continues to attract an average of 2 visits per weekfrom industry, academia and government bodies, with a size of 5-30 per delegation. This includes OEMS like Tata Elxsi, Ashok Leyland, TVS Motors, Tata Metalics, Collins Aerospace, Quest, Boeing, Airbus, Siemens, Tata Steel, MAHE, VIT, various IITs and NITs, private engineering colleges, industry organisations such as ACMA, BCIC, etc.

- These visits and interactions led to 5 new industrial research & innovationprojects in I4.0 such as additive manufacturing, predictive analytics, etc. with Wipro, DEBEL, Harting, Collins, and Garrett Automation, etc. worth INR 3Cr are currently undergoing; another16 projects worth 81Cr are under review by DHI.

- A complete virtual prototyping labwith multiple license Team Centersuite of software has been donated by Siemens that is worth INR 45L. This is being used in the training programmes.

- A number of student-fellowshipshave been funded by industry such as Well Fargo (1 MTech fellowship in smart manufacturing: INR 11Lakhs), Siemens (3 MTech and 1 PhD fellowships in smart manufacturing: INR 88Lakhs).

- STCI funded an advanced computing lab (INR 30Lakhs) to support training using the CEFC smart factory.

- A hackathon in SmartX products(Smart Health, Smart Shop Floor Safety, and Smart Sustainability) conducted with funding of INR 60 Lakhs from Siemens to select, mentor and seed-fund 10start-up ideas.

- Advanced Manufacturing Technology: Proposal on hybrid manufacturing of INR 6.5Crapproved with DST.

- Proposal for Collaborative Robotics approved by DST with a value of INR 50L.

| 3 | |

|---|---|

| Prof. Vijay Kannan, (Vernon and MaRee Buehler Endowed Professor; Head, Department of Management; and Executive Director of International Programs with a faculty along with a 16-membered student group of Utah State University visited the IISc Smart factory at CPDM, Indian Institute of Science (IISc) on March 09, 2023. | As part of the IISc and Office of Naval Research (ONR) meeting on hypersonics, human-machine teaming & aerospace engineering, a team from ONR and DEVCOM Army Research Laboratory visited the IISc Smart factory |

|  |

| A delegation from the University of Liverpool, UK led by Dr Andrew Levers, Executive Director, Institute of Digital Engineering and Autonomous Systemvisited CPDM, Indian Institute of Science (IISc) and the Smart Factory Facility on March 23, 2023. The visit was followed by a discussion on mutual interests and potential collaborations. | A team from KPMG India and ArcelorMittal Nippon Steel India (AMNS) visited CPDM, Indian Institute of Science (IISc), and the Smart Factory facility at CPDM on 05 April 2023 |

CEFC Smart Manufacturing Demo & Development Cell (SMDDC) at CMTI

Theme

The Demo & Development Cell for Smart Manufacturing Demo at CMTI is conceptualized in the scheme proposed below. The complete system is envisaged to work with minimum human interference, adopting latest sensors, actuators technology in the equipments. The communication and transfer of information between elements of the system with the master controller having higher level of computers and managed by very adaptive PLC, and related software is the brain of the system.

Vision

Create a platform at CMTI for Indian manufacturing industries encompassing Machinery OEMs, Sub-System developers, Users, Component manufacturers, Solution developers, startups and so on to explore, experience, experiment, evaluate and adopt Smart Manufacturing / I4.0 technologies with expert assistance from CMTI. Micro Small and Medium Enterprises (MSMEs) in particular, will be benefitted from the Cefc services to gear up for full scale I4.0 based production and enhancing their global competitiveness.

Objectives

- 1. Establish a Smart Manufacturing Demo cum Development Centre (Machine Tool centric) as a pilot implementation of SMART MANUFACTURING at cell level (Technology driver) in INDIA

- 2. Showcase for Industry 4.0 concepts, tools & solutions – capabilities, advantages & limitations (Showcase & Experience Centre - Awareness & Propagation)

- 3. Explore limits of unmanned / automated smart production systems, benchmark I4.0 elements / tools, evaluate system security aspects (R&D)

- 4. Tryout & evaluation facility for solution developers (Enabling localization & customization)

- 5. Develop / Acquire expertise on smart implementations (Best practices)

- 6. Support Industry for rolling out smart production systems (Consultation – configuration, selection, viability analysis, etc. customized solution - development & deployment, Technology transfer & handholding)

Skill Development Programs:

- Awareness initiatives: 4,050 participants.

- Internships: 153 engineering students completed internships.

- Project work: 38 engineering students were engaged in project work.

- Executive training programs: 150 industry executives underwent training programs.

- Hands-on Training on Industry 4.0: Training provided to 300+ trainee engineers, over 100 engineering students and 20+ faculties,

- Design Innovation clinics: 2 clinics conducted, involving 150 engineering students.

- Apprenticeship: 150 engineers participated in apprenticeship programs.

Major Events conducted:

- National Conference on Robotics: 3rd-4thJuly 2023 at CMTI Bengaluru 314 delegates attended

- Workshop on IIOT Implementation in Metal Casting & Demonstration of Integrated Smart Foundry system 28thAugust at CMTI Bengaluru: 115 delegates Attended

- Industry Interaction Meet and Workshop on Smart & Digital Manufacturing at CMTI regional Centre at Rajkot on 11thMarch, 2023: 150 persons from industry participated

Augmentation of Centre for Industry 4.0 & Data Engineering Skill Development Centres at 10 different locations of India

Shaping the Future of Manufacturing

We are committed to envisioning and influencing the future of manufacturing in India. Through collaboration, research, and advanced technologies, we aim to bring transformative changes to the industry.

Speeding Up the Adoption of Industry 4.0 Solutions

Our goal is to accelerate the adoption of Industry 4.0 solutions, ensuring that industries across the nation embrace digitalization, automation, and advanced manufacturing practices.

Harnessing the Power of Digital Transformation:

Recognizing the potential of digital transformation, C4i4 promotes collaboration and knowledge sharing to fully utilize the capabilities of digital technologies.

Execution methodology:

C4i4 has formed a dedicated team of professionals, including Operations Associates, Procurement Executives, Project Management Associates, and seasoned Industry Experts, to lead the execution of the iFactory network project. The creation of a single iFactory is a well-structured process completed over a span of 16 weeks, involving several key steps:

| Associates | Executives |

|---|---|

| 1. Partner Evaluation | 5. Procurement |

| 2. Finalization of the MoU | 6.Installation & Commissioning |

| 3. Onboarding Execution team | 7.Training of the Managers @ EC |

| 4. Site Readiness | 8. Handover |

Throughout the entire 16-weeks duration, a dedicated C4i4 Project Management Associate is stationed at the project site, while other team members and vendors travel to the site as needed. This approach ensures the smooth execution of the project

Monthly Report of C4i4 (October)

Monthly Report of C4i4 (November)