सीएमटीआई के बारे में

केंद्रीय विनिर्माणकारी प्रौद्योगिकी संस्थान (सीएमटीआई), भारी उद्योग मंत्रालय (एमएचआई), भारत सरकार के अधीन एक स्वायत्त अनुसंधान एवं विकास संस्थान है, जो विनिर्माण क्षेत्र में नवाचार और प्रगति के क्षेत्र में कार्यरत है। 4पी चुनौतियों - उत्पाद, प्रक्रिया, जन और उत्पादन - को ध्यान में रखते हुए दृढ़ प्रतिबद्धता के साथ सीएमटीआई अत्याधुनिक विज्ञान और प्रौद्योगिकी समाधानों के माध्यम से अपने प्रयासों को आगे बढ़ा रही है।

सीएमटीआई का मुख्य उदेश्य उभरती हुई मशीन और विनिर्माण प्रक्रिया प्रौद्योगिकियों को उपलब्धन कराने का प्रयास करना है जो न केवल भारत के लिए नई हैं बल्कि वैश्विक प्रगति में भी सबसे आगे हों। संस्थान ग्राहकों और उद्योगों की विशिष्ट आवश्यकताओं को पूरा करने के महत्व को भी पहचानता है। इस दृष्टिकोण के अनुरूप, सीएमटीआई विशिष्ट और अनुकूलित मशीनें, प्रक्रिया प्रौद्योगिकी और स्वचालन प्रणाली विकसित करता है। अपने ग्राहकों की विशिष्ट आवश्यकताओं को पूरा करने के लिए समाधानों को तैयार करके, सीएमटीआई यह सुनिश्चित करता है कि यह एक विश्वसनीय भागीदार बना रहे, व्यवसायों को उनके संबंधित कार्यक्षेत्र में बढ़ने और उत्कृष्टता प्राप्त करने के लिए सशक्त बनाता है।

इसके अलावा, सीएमटीआई उच्च मूल्यवर्धित तकनीकी सेवाएं प्रदान करके उत्पाद विकास से ऊपर भी अपना प्रभाव बढ़ाती है। इन सेवाओं के माध्यम से, संस्थान उद्योग और शैक्षणिक कर्मियों के कौशल और पुन: कौशल को बढ़ावा देती है, जिससे अंततः क्षमता निर्माण और उत्पादकता में वृद्धि होती है। व्यक्तियों की प्रतिभा और क्षमताओं का पोषण करके, सीएमटीआई उन्हें अपनी क्षमताओं को आगे बढ़ाने और विनिर्माण क्षेत्र की समग्र उन्नति में योगदान करने के लिए सशक्त बनाती है।

संक्षेप में, केंद्रीय विनिर्माणकारी प्रौद्योगिकी संस्थान (सीएमटीआई) एक अग्रणी शक्ति के रूप में खड़ा है, जो विज्ञान, प्रौद्योगिकी और नवाचार पर अपने अटूट फोकस के माध्यम से विनिर्माण परिदृश्य को आकार देने के लिए समर्पित है। नई प्रौद्योगिकियों के विकास को बढ़ावा देकर, ग्राहकों की जरूरतों को पूरा करके, मूल्यवान सेवाएं प्रदान करके और उन्नत प्रौद्योगिकी के माहौल को बढ़ावा देकर, सीएमटीआई विनिर्माण उद्योग में विकास, प्रगति और उत्कृष्टता के उत्प्रेरक के रूप में अपनी स्थिति को मजबूत कर रही है।

तदनुसार, सीएमटीआई गतिविधियों के चार स्तर हैं:

- पहला स्तर है, उभरती हुई मशीन और विनिर्माण प्रक्रिया प्रौद्योगिकियों को विकसित करना जो दुनिया के लिए नहीं तो भारत के लिए नई हों।

- दूसरा स्तर है, ग्राहकों की आवश्यकताओं को पूरा करने के लिए विशेषीकृत और अनुकूलित मशीनें, प्रक्रिया प्रौद्योगिकी और स्वचालन प्रणाली विकसित करना।

- तीसरी स्तर है, गतिविधि उच्च-मूल्य वर्धित तकनीकी सेवाएं प्रदान करने, उद्योग और शैक्षणिक जनशक्ति के कौशल और पुन: कौशल प्रदान करने पर केंद्रित है, जिससे उनके व्यवसाय में क्षमता निर्माण और उत्पादकता में वृद्धि हो सके।

- चौथी महत्वपूर्ण गतिविधि में मशीनों, प्रक्रियाओं और संबद्ध क्षेत्रों के चुने हुए क्षेत्रों में उन्नत प्रौद्योगिकी मध्यवर्तन, प्रौद्योगिकी लाइसेंसिंग, उद्भवन, उद्यमिता और खुले समावेशी नवाचार को बढ़ावा देना है।

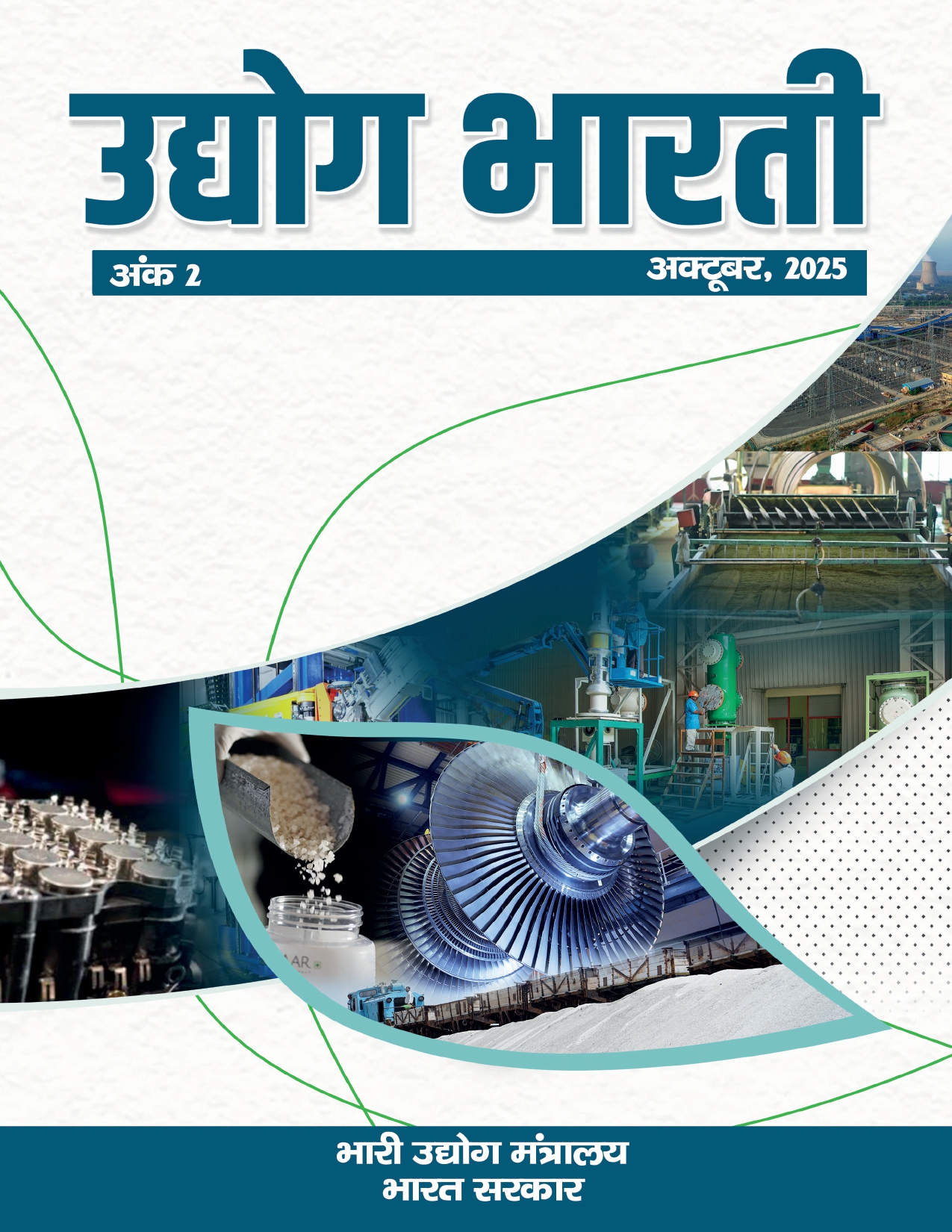

केन्द्रित कार्यक्षेत्र

मशीन और विनिर्माण विज्ञान के चयनित क्षेत्रों में आत्मनिर्भरता को साकार करने में सीएमटीआई किस तरह से और कैसे योगदान देगा, इसमें निम्नलिखित शामिल हैं।

"आज सीएमटीआई अनुसंधान प्रक्रिया प्रौद्योगिकी और मशीनें विकसित करने जनशक्ति को प्रशिक्षित करने और औद्योगिक अनुप्रयोगों में तैनात करने का कार्य करती है"

- अल्ट्रा-प्रिसिजन मशीन टूल्स

- विशेष प्रयोजन मशीनें और उपकरण

- सेंसर और नियंत्रण

- कपड़ा मशीनरी

- स्मार्ट विनिर्माण और उद्योग-

- योगात्मक और विशेष विनिर्माण प्रक्रियाएं

- प्रिसिजन मेट्रोलॉजी

- विमान एलआरयू और परीक्षण रिंग और क्वालिफिकेशनns

- कौशल और पुन: कौशल - उद्योग के लिए तैयार जनशक्ति प्रशिक्षण

- प्रौद्योगिकी लाइसेंसिंग और इंकुबेशन

मूल्य वर्धित तकनीकी सेवाएँ

सीएमटीआई अत्याधुनिक उपकरणों और यंत्रों से सुसज्जित है। हम कई प्रकार की प्रयोगशाला सेवाएँ प्रदान कर रहे है।

- मशीन टूल और उसके समुच्चय: मशीन (क्वालिफिकेशन) प्रदर्शन परीक्षण, सुरक्षा, कंपन और ध्वनि।

- माप और अंशांकन: सीएमटीआई एनएबीएल प्रमाणित प्रयोगशाला है। हम मेट्रोलॉजी प्रयोगशालाओं में उपयोग किए जाने वाले लेजर इंटरफेरोमेट्री और मास्टर्स के कैलिब्रेशन जैसी उच्च-स्तरीय सेवाएं प्रदान करते है।

- उच्च मूल्य वाले प्रतिस्थापन घटकों और उपप्रणालियों की री-इंजीनियरिंग: उच्च मूल्य वाले घटकों के प्रतिस्थापन और मरम्मत के लिए सीएमटीआई से धातु आधारित एडिटिव मैन्युफैक्चरिंग (3डी-प्रिंटिंग) सेवाओं का लाभ उठाया जा सकता है।

- यरोस्पेस योग्यता परीक्षण: एयरोस्पेस प्रयोगशाला सीएमटीआई में परीक्षण रिग के डिजाइन सहित योग्यता परीक्षण किया जाता है। हम इस प्रकार की सेवाएं प्रदान करना चाहेंगे।

- सामग्री परीक्षण और धातुकर्म परीक्षण: बेहतर गुणवत्ता प्रबंधन प्रणालियों और मानकों के कार्यान्वयन सहित विभिन्न परीक्षण सेवाएं सीएमटीआई में उपलब्ध हैं।

- नैनो विनिर्माण और नैनो कैरेक्टैराइजेशन सेवाएँ:

- नैनो-विनिर्माण: सीएमटीआई धातुओं पर 8 नैनोमीटर जितनी छोटी कृति बना सकती है;

- नैनोमटेरियल कैरेक्टैराइजेशन: नैनोमटेरियल और सतह लक्षण वर्णन के लिए आवश्यक सभी सुविधाएं सीएमटीआई में स्थापित की गई हैं। हम पहले से ही अकादमियो और एजेंसियों जैसे आरडीएसओ को 25% रियायती दरों पर ये सेवाएं प्रदान कर रहे हैं और आरडीएसओ ने सीएमटीआई को उनकी आपूर्ति श्रृंखलाओं के लिए प्रमाणित एजेंसी के रूप में मान्यता दी है।

कौशल और पुनःकौशल

- प्रशिक्षण कार्यक्रम: कामकाजी पेशेवरों के लिए प्रतिवर्ष लगभग 55 प्रशिक्षण कार्यक्रम (2 - 5 दिन) पेश किए गए हैं। इसके अलावा, 15-30 दिनों की अवधि के अनुकूलित कॉर्पोरेट प्रशिक्षण कार्यक्रम आयोजित किए गए है।

- इंजीनियरिंग छात्रों के लिए सक्रिय शिक्षण कार्यशालाएँ: सीएमटीआई इंजीनियरिंग स्कूलों में पढ़ने के दौरान व्यावहारिक कौशल सिखाने के लिए अनुकूलित कार्यक्रम विकसित करेगी। कई इंजीनियरिंग स्कूलों में इसका काफी कमी है। कर्नाटक सरकार को इस दिशा में कुछ करना चाहिए, सीएमटीआई इस संबंध में सहयोग देना चाहेगी।

- फिनिशिंग स्कूल: सीएमटीआई पास आउट इंजीनियरिंग छात्रों के लिए 3 - 6 महीने के फिनिशिंग स्कूल शुरू करने की योजना बना रही है ताकि उन्हें उद्योग में रोजगार योग्य जनशक्ति बनाया जा सके।

- ग्रीष्मकालीन इंटर्नशिप: सीएमटीआई ने पहले ही 2 महीने की सालाना 200 इंटर्नशिप की पेशकश करते हुए, ग्रीष्मकालीन इंटर्नशिप शुरू कर दी है।

- एमएसएमई कार्यबल के लिए ऑनलाइन स्व-शिक्षण पाठ्यक्रमों का डिज़ाइन: ये कार्यक्रम मुख्य रूप से स्व-शिक्षण, स्मार्ट विनिर्माण से संबंधित समस्या निवारण सलाह पर केंद्रित हैं।

चित्र.1: सीएमटीआई आर एंड डी फोकस-मशीनों का विकास, प्रक्रिया, टीआईसी सेवाएं और प्रशिक्षण

चित्र..2: सेंसर प्रौद्योगिकी विकास सुविधाएं

चित्र. 3: स्मार्ट विनिर्माण विकास और प्रदर्शन केंद्र

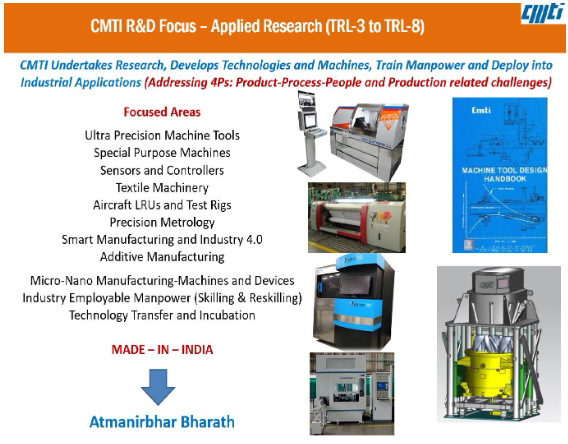

चित्र. 4: सीएमटीआई अपनी प्रौद्योगिकियों को वाणिज्यिक बाजार में लॉन्च करने के लिए उद्योगों को लाइसेंस देता है

वेबसाइट का यूआरएल- https://cmti.res.in